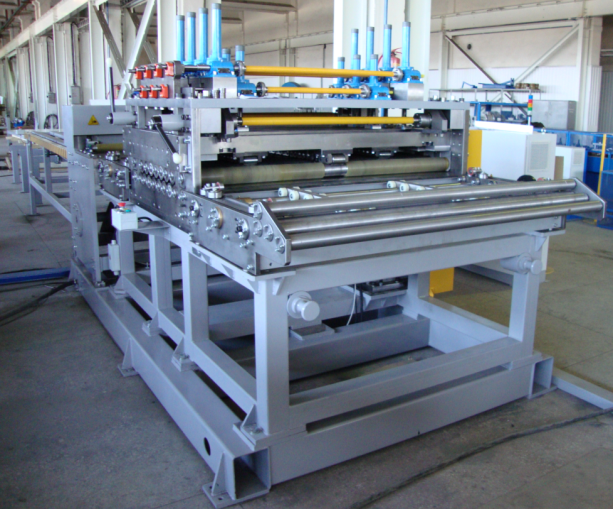

AMTengineering is engaged in designing and manufacturing of wide range of automated lines for slitting and cutting-to-length of sheet metal materials. This equipment is widely used in automotive, ship building, aircraft building industries and in construction materials production.

SLITTING LINE

SLITTING LINE is designed for slitting sheet metal (with zinc or polymer coating and with width up to 1500 mm and thickness up to 3.0 mm) with further recoiling of the strips.

| Line | Material width, mm | Material thickness, mm | Coil weight, t | Slitting speed, m/min |

| LR 1210…1230 | 500 – 1250 | 0,4 – 3,0 | 8-10 | 25 |

| LR 1510…1530 | 500 – 1500 | 0,4 – 3,0 | 10-15 | 25 |

The line consists of:

- Decoiler;

- Straightener;

- Slitter;

- Roller table;

- Handling system;

- Recoiler.

CUTTING-TO-LENGTH

CUTTING-TO-LENGTH line is designed for cutting sheet metal (with zinc or polymer coating and with width up to 1500 mm and thickness up to 5.0 mm) crosswise into sheet pieces.

| Line | Material width, mm | Material thickness, mm | Coil weight, t | Slitting speed, m/min |

| LPR1210…1230 | 500 – 1250 | 0,4 – 3,0 | 8-10 | 25 |

| LPR1510…1550 | 500 – 1500 | 0,4 – 5,0 | 10-15 | 25 |

The line consist of:

- decoiler;

- powerful high-load straightener;

- cross guillotine with a clamping system;

- operating system with control of cut sheets length;

- stacking device.

SLITTING AND CUTTING-TO-LENGTH

SLITTING AND CUTTING-TO-LENGTH line is designed for longitudinal and cross cutting of sheet metal (with zinc or polymer coating and with width up to 1500 mm and thickness up to 3.0 mm).

| Line | Material width, mm | Material thickness, mm | Coil weight, t | Slitting speed, m/min | Sheet length, mm |

| LPPR 1210…1230 | 500 – 1250 | 0,4 – 3,0 | 8-10 | 25 | 500 – 6000 |

| LPPR 1510…1530 | 500 – 1500 | 0,4 – 3,0 | 10-15 | 25 | 500 – 6000 |

The line consist of:

- decoiler ;

- powerful high-load straightener;

- spooler;

- slitter;

- cross guillotine with holding system;

- operating system with control of the cut sheets length;

- stacking device;

- handling system;

- recoiler.

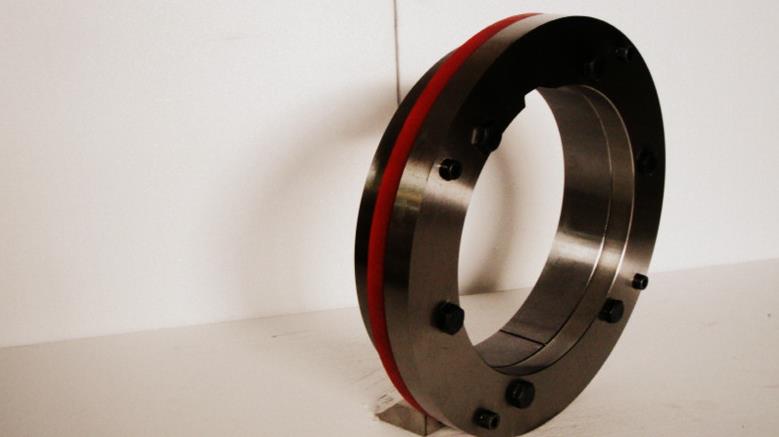

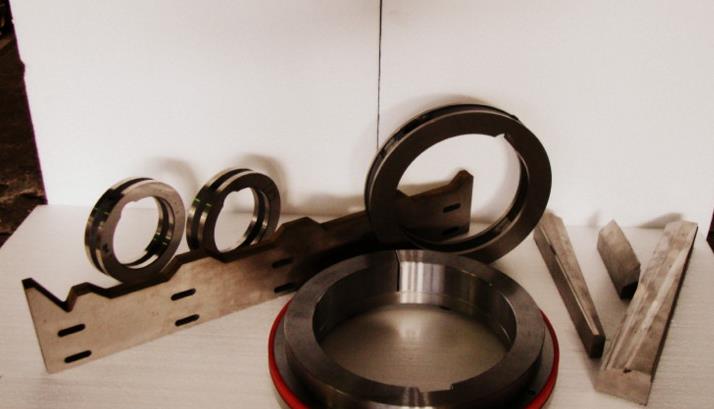

CUTTING KNIVES AND GUILLOTINES

Our company has high requirements to the cutting knives for cutting all types of metal profile. They must ensure cutting the material of the required thickness at the required speed and to maintain their quality throughout their life’s span.

The unique technology and use of high-precision erosion, grinding and milling machines followed by heat treatment allow to achieve the necessary accuracy and quality in accordance with the technical parameters of automatic lines. The list of knives ranges from guillotines to disc knives for slitting and slitting and cut-to-length lines.

ZMM Pobeda is also engaged in designing and manufacturing of wide range of automated lines for slitting and cutting-to-length of sheet metal materials. This equipment is widely used in automotive, ship building, aircraft building industries and in construction materials production

SLITTING LINE

Line application: longitudinal cutting of coils into several smaller widths strips. After longitudinal cutting, this line is used for automatic coiling of the produced strips. Those smaller width coils are then used in roll forming lines, tube mill lines, press machines, etc.

The main Slitting Lines technical data:

- Material thickness range, mm: 0.15-1.0/0.4-3.0/1.5-10

- Coil width range, mm: 1000/1250/1500/1800/2050

- Coil weight range, ton: 10/15/20/30/35

- Overall coil diameters: 1500/1800/2100

- Working speed range, m/min: 0-300, depending on the initial material thickness

- Special devices offered for these lines:

- Four-arm tooling change-over sets

- Four-arm turnstile

- Others, depending on special customer orders

CUT TO LENGTH LINES (CTL LINES)

Line application: transverse cutting of coils into sheets of identical width, but different length in accordance with the PLC program. Together with the process of transverse cutting of the initial material that line automatically arranges the cut sheets into packets. The cut sheets are then used for shearing to necessary dimensions, bending with press-brakes, laser, gas, or plasma cutting to produce flat products.

The main CTL Lines technical data:

- Material thickness range, mm: 0.4-3.0/1-4/1.5-6/2-8

- Coil width range, mm: 1000/1250/1500/1800/2050

- Coils weight range, ton: 10/15/20/30/35

- Overall coil diameter, mm: 1500/1800/2100

- Working speed range, m/min:

- 0-40 with flying shear

- 0-70 with rotary shear

- Cut sheet length, m: 0.5 – 12

- Packet weight, ton: 2.5/4/6/12

COMBO LINES

Line application: longitudial cutting of coils into strips and cutting of these strips into sheets. Those lines also have combined main technical characteristics of Slitting Lines (only slitting initial material into strips and then coiling of those strips) and CTL Lines (only cutting the initial material transversally into sheets).

The main Combo Lines technical data:

- Material thickness range, mm: 0.4-2.0

- Coil width range, mm: 1000/1250/1500

- Coil weight range, ton: 10/15

- Overall coil diameter [mm] : 1500 / 1600

- Working speed range, m/min: 0-30

- Maximum number of longitudinal cuts: 6

SPECIAL COIL RE-WINDING AND UN-WINDING LINES

Line’s functions: coil re-winding and un-winding. They are using in Metal Steel Centers for unwinding a small part of material from mother coil and rewinding that material in a baby coil.

Main technical data:

- Material thickness range, mm: 0,4-2,0

- Coil width range, mm: 1000 / 1250 / 1500

- Mother coil weight range, ton: 10 / 15

- Baby coil weight range, ton: 5 / 7,5

- Max. overall coil diameter, mm : 1500

- Working speed range, m/min: 0-60