Click on each tab below to read more.

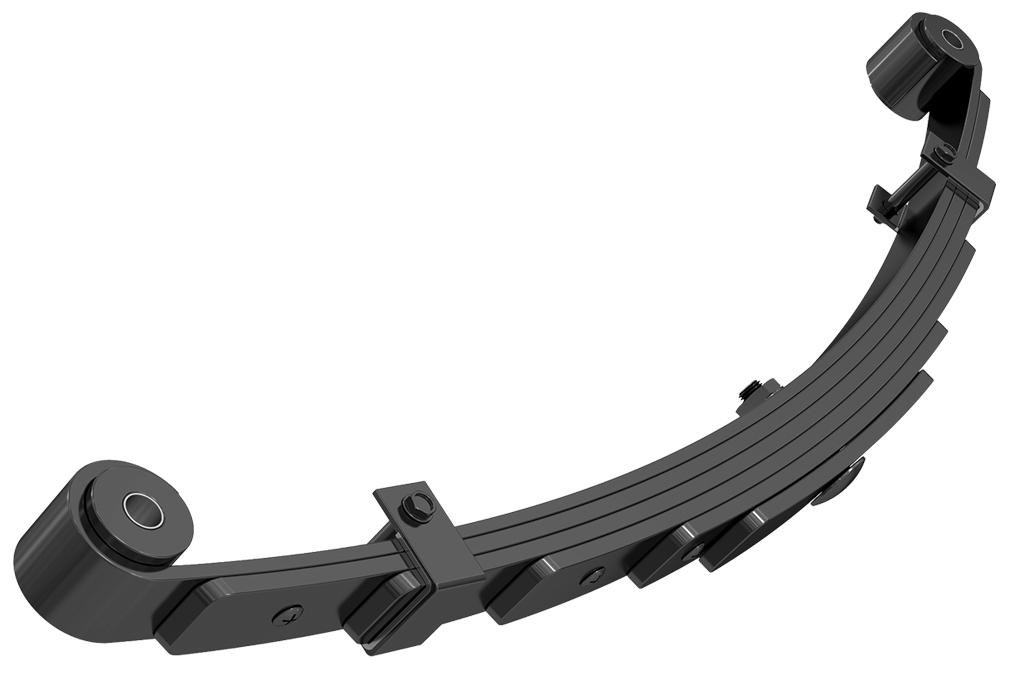

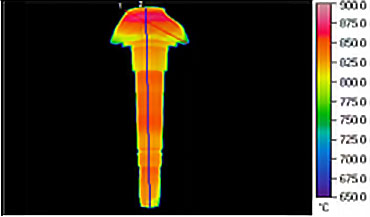

The conventional heat treat process for hypoid drive pinion is gas carburizing with oil quench. Conventional induction contour hardening is highly complicated due to the complex part geometry. The TSH technology makes induction contour hardening of this part practical.

- CV Hypoid Pinion:

- Length: 270 mm (10.6 “)

- Teeth: 7

- Module: 0.5

- Weight: 6.3kg (14#)

- Steel type: 60LH

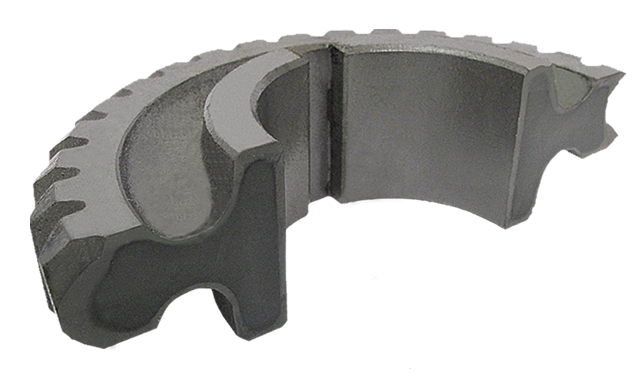

2nd Generation LH60 & LH80 steels provided for Light Axle Pinion

Fatigue Testing

- 60LH B10 = 685,524 cycles

- 80LH B10 = 671,505

- 8625H B10 = 191,252 (Carburized Production)

Residual Stress

- 60LH -100 to -135 ksi

- 8625H -20 to -35 (Carburized)

Replaces carburizing and alloy steels and a better option than induction hardening

- Cycle reduction from 8-15 hrs to 1-2 minutes

- Strength improvement 1.10+

- Impact strength 1.7+

- Fatigue limit improvement 1.5+

– – –

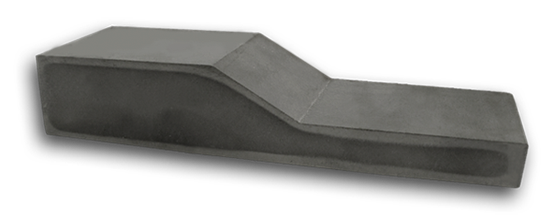

- Belcard is the largest supplier of drive shafts in the FSU

- Belcard journal crosses are made using LH steels and TSH process.

- Successfully tested by US manufacturers

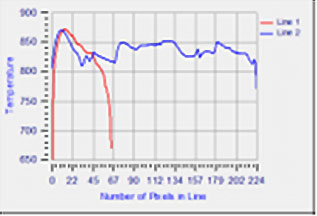

Thermal Imaging

Quenching

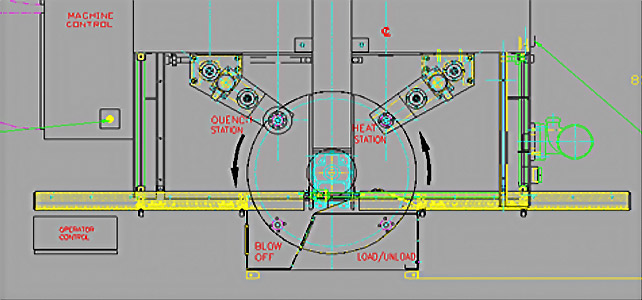

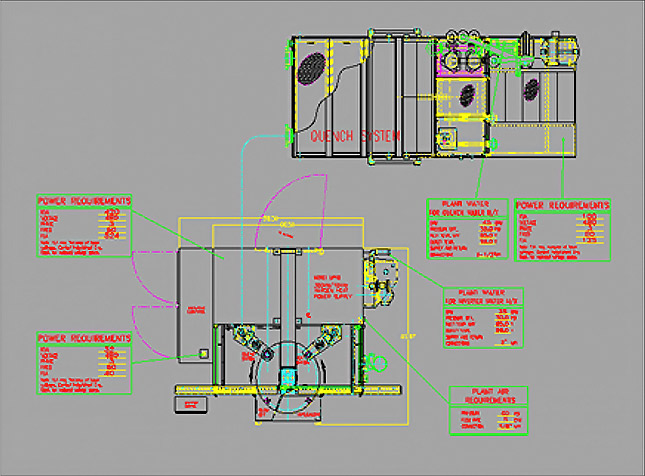

Induction Heating And Quenching