Click on each tab below to read more.

TSH & LH STEEL TECHNOLOGY:

- Novel steel technology was developed

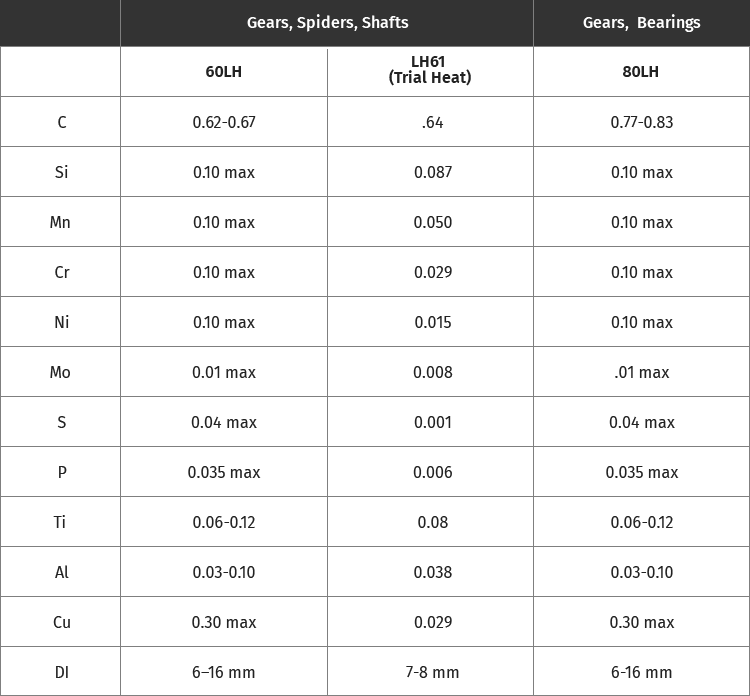

- Low hardenability

- DI <16mm for LH steels

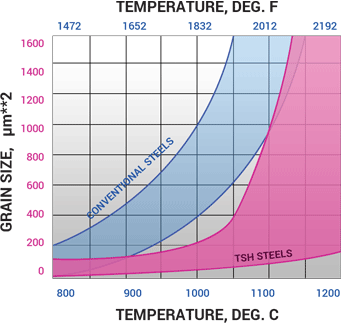

- Extremely low probability of austenite grain growth

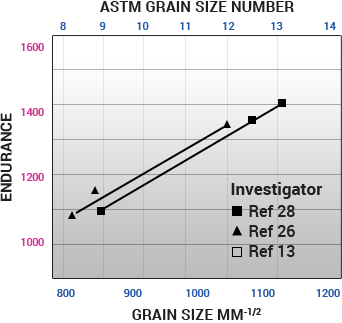

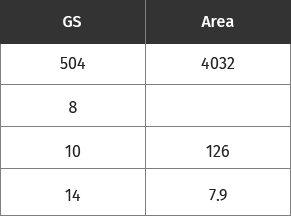

- Very Fine Grain Size (GS 9-12)

- Low hardenability

- Improved forgeability

- Acceptable machinability

- Lower propensity for distortion and cracking during quenching

- 3rd generation LH steels are now available

- Improved hardenability control (+/- 1 mm)

- Lower minimum hardenability (DI=6 mm)

- Allows thinner cross sections to be heat treated

- Finer grain size (GS 11-13)

61 LH TRIAL HEAT

- Trial Heat Cast at WSH in February 2014

- 84 tons of LH61 steel strand cast

- 2 Billet sizes

- 5.125 Square for rolled flats

- 6.25 Square for rounds

- 25 billets available for rolling

- • Rolling was performed at KES

- Rounds Sizes, 2.875”, 3” & 3.75”

- Rolled flats in March 2014

- Rolled Rounds in 2014 & 2015

- 2.875” Bar available

- 3.75” Bar available

- • LH Steel Quality – Significant Improvement